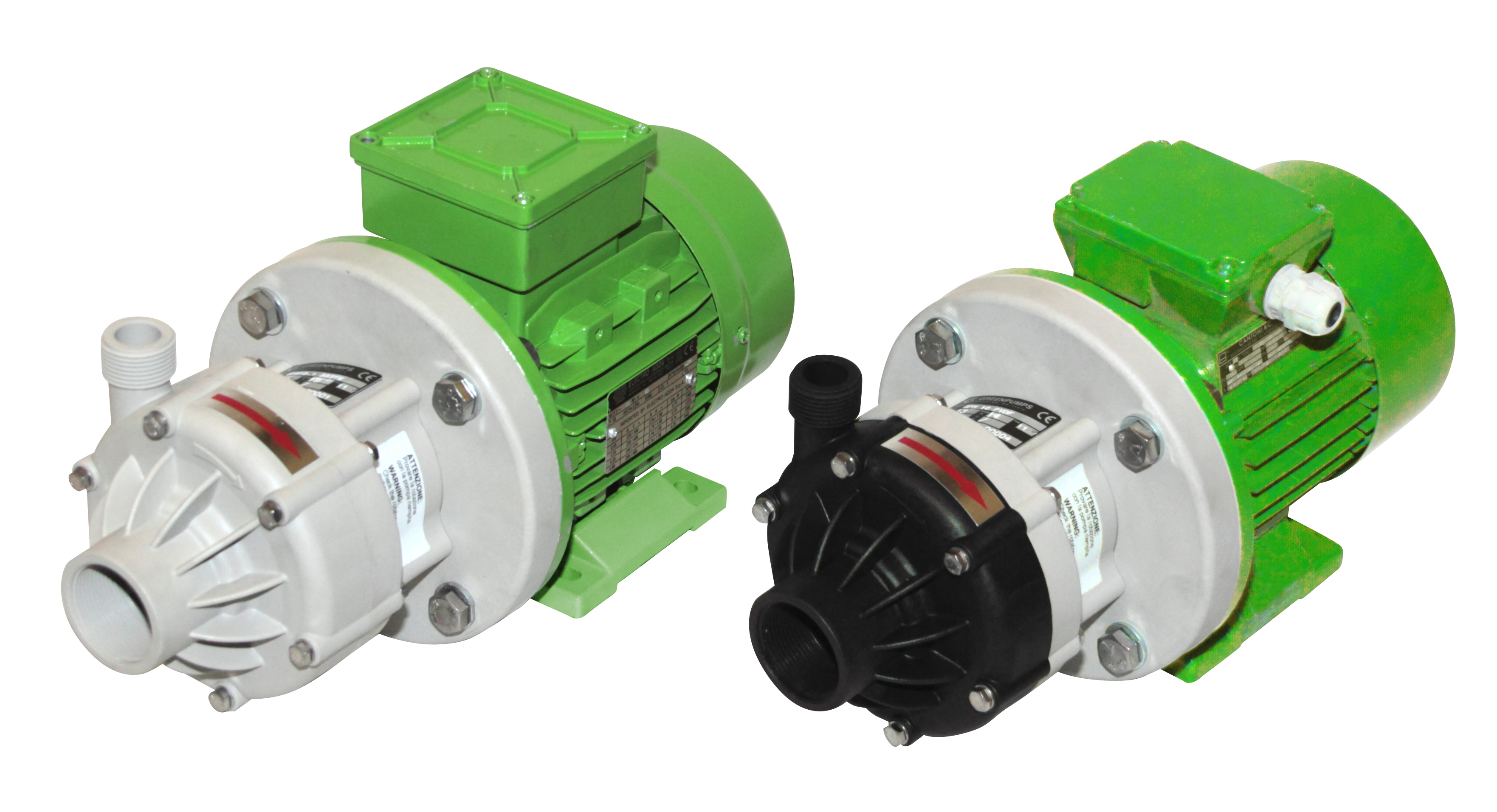

GPM – Caster M

Beschreibung

GPM – Caster M

GREENPUMPS GPM Sealless Plastic Injected Molded Centrifugal pumps are designed and fabricated for light duty and transfer applications.

GPM pumps are fabricated with plastic injected molded technology to resist internal and / or external corrosion.

Pump materials filled with fiberglass or fibre carbon are designed to handle difficult solutions such as strong acids and difficult chemical compounds in chemical, OEM or industrial applications.

All GREENPUMPS pumps, due to the construction features are thought to have zero leakages even in extreme working conditions.

The absence of mechanical seal or packing gland eliminates dangerous emission in order to protect the environment and workers.

Specification

Withstands external corrosion

Oversized, high purity ceramic thrust bearings and shaft

Chemically resistant channelled PTFEC carbon sleeve bearings

Modular Impeller allows for modifying performances

Direct starting motors possibility

Mounting Close Coupled NEMA and IEC

Replaceable adaptor motor flange NEMA and IEC on the same coupling housing

Separate universal hubs on external magnet ring, reduce inventory costs dramatically and increase flexibility

External magnet with protection of magnetic parts, against mechanical damages during assembly

Low maintenance costs thanks to replaceable impeller

High MTBF (mean time between failure)

Pumps are in accordance to ATEX regulation category EX II 2 G

Features

GREENPUMPS GPM Plastic Centrifugal Injected Molded pump can maintain design head and flow for an extended running period.

Produkteigenschaften

| Förderhöhe max | 25 Meter |

| Fördermenge max | 30 m³/h |

| Temperatur min PVDF | -10 °C |

| Temperatur max PVDF | 90 °C |

| Temperatur min PP | -10 °C |

| Temperatur max PP | 65 °C |

| max. spezische Dichte Fördermediums | 2 kg/dm³ |